Covariant

Open siteOther

Introduction

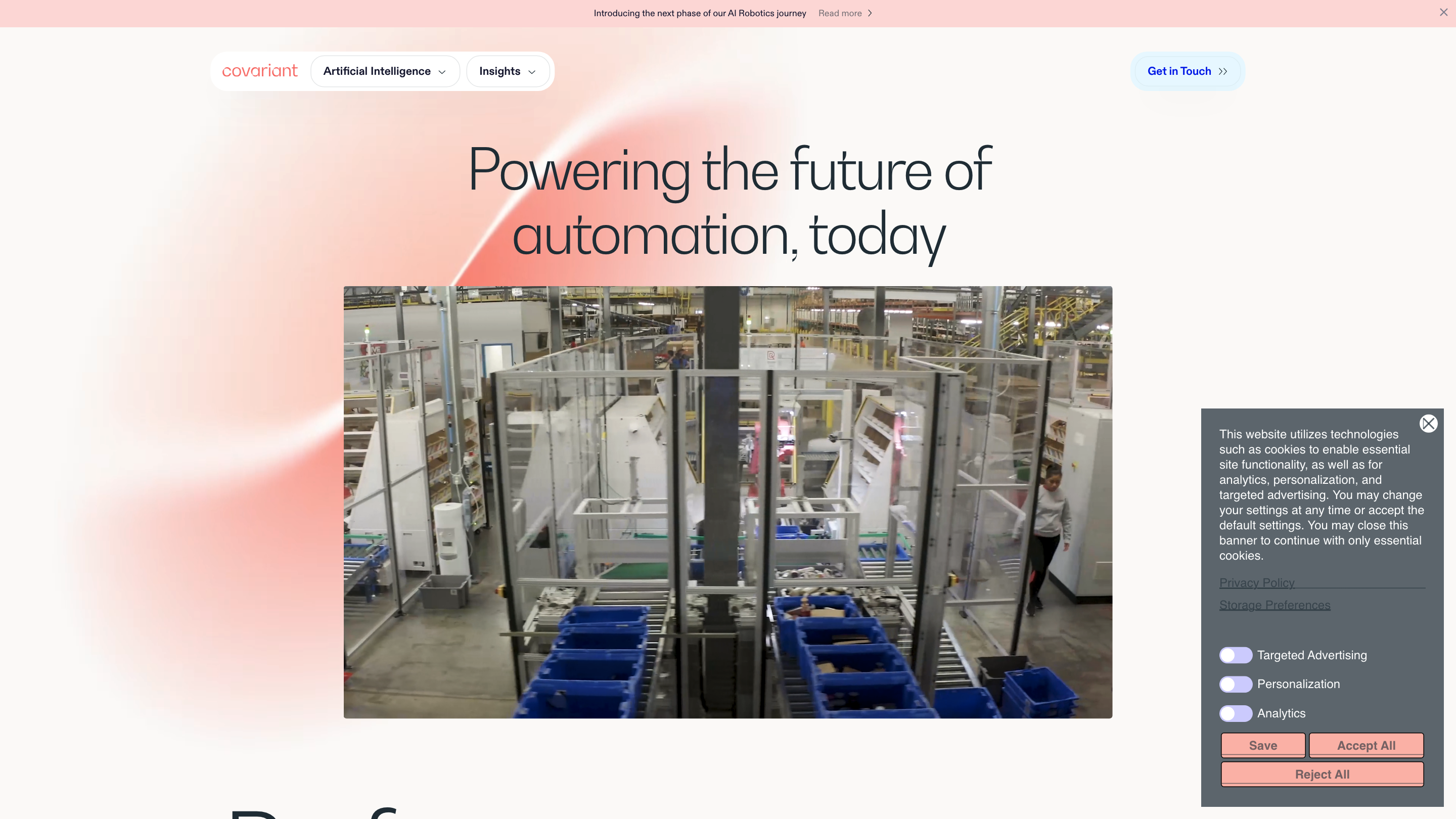

Powering the future of automation

Covariant Product Information

Covariant Brain: AI Robotics platform powering the future of automation

Covariant Brain is an AI-powered robotics platform designed to enable autonomous, high-performance picking and automation across warehouse operations. Trained on a vast multimodal robotics dataset gathered from warehouses worldwide and powered by the RFM-1 framework, Covariant Brain aims to achieve human-level autonomy on Day One, driving efficiency, accuracy, and scalability for fulfillment centers and distribution networks.

Overview

- Purpose-built for warehousing: Automates a wide range of picking use cases and adapts to dynamic demand and changing product mixes.

- Fleet-scale learning: Leverages learnings from the Covariant network to continually improve performance across multiple robots and facilities.

- Industry-ready: Trusted by leading fulfillment companies to address labor gaps, fluctuations in demand, and throughput requirements.

How It Works

- Unified AI Robotics Platform: The Covariant Brain integrates perception, planning, and manipulation to enable robots to pick virtually any SKU on Day One.

- Multimodal Training: Trained on millions of episodes across diverse warehouse scenarios, enabling robust grasping, robust object recognition, and adaptable manipulation.

- Fleet Learning: Robots share experiences to accelerate learning across the fleet, reducing time to value for new environments.

- Dynamic Adaptation: Designed to handle changing and dynamic business needs, enabling quick reconfiguration for new SKUs and workflows.

Use Cases

- Autonomous order picking and item localization

- Sorting, packing assistance, and replenishment tasks

- Handling fluctuating demand and seasonal spikes

- Scalable deployment across multiple warehouse locations

Safety and Compliance

- Designed to operate in industrial environments with robust perception and collision avoidance

- Adheres to standard safety practices for automated warehouse systems

Core Features

- End-to-end AI robotics platform for warehouse automation

- Day One autonomy with multi-SKU picking capabilities

- Multimodal perception and manipulation trained on large industrial datasets

- Fleet learning to share knowledge across robots and facilities

- Robust handling of dynamic and changing business needs

- Scalable deployment across multiple warehouses and locations

- Trusted by top fulfillment companies for labor efficiency and throughput

- Privacy-conscious data handling with enterprise-grade security